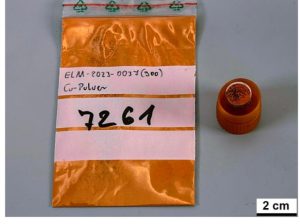

ULTRAFINE COPPER POWDER

We have two types of Ultrafine Copper Powder:

- Ultrafine Copper Powder with a copper content of 99.9343%. Its particle size falls within a fine range of 0.4 to 0.7 nanometers and a coarse range of 1.5 to 6.0 nanometers.

- Ultrafine Copper Powder with a copper content of 98.8048%. Its particle size falls within a fine range of 0.3 to 0.5 nanometers and a coarse range of 1.0 to 2.0 nanometers.

Ultrafine copper powder, also known as nanoscale copper powder or copper nanoparticles, possesses several characteristics that provide advantages in various applications. Some of these characteristics include:

- Extremely small particle size: Ultrafine copper particles have a particle size in the nanoscale, meaning their dimensions are on the order of nanometers (less than 100 nanometers). This small size provides a larger surface area compared to conventional copper particles, which is beneficial in many applications.

- High chemical reactivity: Due to their size, copper nanoparticles are highly chemically reactive. This makes them useful in catalysts, oxidation-reduction reactions, and applications requiring high surface activity.

- Good electrical and thermal conductivity: Copper is known for its excellent electrical and thermal conductivity. Ultrafine copper nanoparticles maintain these properties, making them suitable for use in advanced electronic devices, conductive coatings, and heat dissipation systems.

- Enhancement of strength and hardness in composite materials: When incorporated into composite materials, such as polymer or ceramic composites, copper nanoparticles can significantly improve mechanical properties like strength and hardness without sacrificing electrical or thermal conductivity.

- Antimicrobial properties: Copper nanoparticles exhibit antimicrobial properties, making them useful in medical applications and the manufacturing of antibacterial coatings, bandages, and packaging materials that help prevent the proliferation of microorganisms.

- Applications in electronics and energy: Due to their excellent electrical conductivity, ultrafine copper is used in the fabrication of advanced electronic components, battery electrodes, sensors, and microelectronic devices.

- Efficient catalyst: Ultrafine copper nanoparticles are employed as efficient catalysts in various chemical reactions, including hydrogenation and catalytic oxidation.

- Material consumption reduction: Because of their high surface activity and chemical reactivity, ultrafine copper nanoparticles are often used in minimal quantities, which can reduce material consumption in certain applications.

- Magnetic and optical properties: Depending on their size and shape, ultrafine copper nanoparticles can exhibit unique magnetic and optical properties, making them interesting for applications in nanotechnology and advanced materials science.

In summary, ultrafine copper powder offers several advantages due to its extremely small particle size, high chemical reactivity, excellent conductivity, and antimicrobial properties, making it valuable in a wide range of industrial, scientific, and medical applications.

ULTRAFINE COPPER POWDER WITH PARTICLES SMALLER THAN 1 NANOMETER

When particles of a material are smaller than 1 nanometer in size, meaning they are in the nanoscale range, several advantages and unique properties can be obtained that can be beneficial in various applications. Some of the advantages of having particles smaller than 1 nanometer in size include:

- Larger surface area: Smaller particles have a larger surface area compared to larger particles of the same material. This means there is more surface area available to interact with other materials, which can be beneficial in chemical processes and surface reactions.

- Higher chemical reactivity: Due to their high surface-to-volume ratio, smaller particles exhibit higher chemical reactivity. This allows them to participate in chemical reactions more efficiently and often at faster rates. Therefore, nanoscale particles are useful in catalytic applications and chemical product synthesis.

- Improved electrical and thermal conductivity: In some cases, nanoscale particles can have enhanced electrical and thermal conductivity properties compared to their larger counterparts. This is particularly important in electronic and heat dissipation applications.

- Unique optical and magnetic properties: Nanoscale particles can exhibit unique optical and magnetic properties due to their size and structure. This is relevant in applications such as nanotechnology, materials electronics, and device manufacturing.

- Enhancement of mechanical properties in composite materials: When incorporated into composite materials, such as polymer nanocomposites, nanoscale particles can significantly improve mechanical properties without significantly increasing the material’s weight.

- Greater efficiency in drug delivery systems: Nanoparticles with nanoscale dimensions are used in drug delivery systems because of their ability to transport and release drugs in a more controlled and efficient manner in the body.

- Applications in nanotechnology and nanoelectronics: Nanoscale particles are essential in the fabrication of nanoscale devices and components, which is critical in fields like nanotechnology and nanoelectronics.

- Improved dispersion and stability: In liquid or dispersed systems, nanoscale particles tend to remain in suspension for longer periods and form more stable dispersions due to their size and high surface area.

In summary, having particles smaller than 1 nanometer in size offers several advantages due to their larger surface area, higher reactivity, improved properties, and specific applications in fields such as nanotechnology, chemistry, electronics, and medicine. These advantages make nanoparticles valuable in a variety of scientific, technological, and industrial applications.

CHOICE BETWEEN % COPPER VS. PARTICLE SIZE

The choice between an Ultrafine Copper Powder with 99.99% copper content and particles larger than 1 nanometer or one with 98.8% copper content but with particles smaller than 1 nanometer will largely depend on the specific application for which the copper powder is required, and the particular properties being sought.

Here are some considerations to take into account:

- Copper purity: Copper powder with 99.99% copper content is extremely pure and is preferable in applications where metal purity is critical, such as high-precision electronics or the manufacturing of electrical components. In contrast, powder with 98.8% copper content would contain more impurities.

- Particle size: If the application requires a high surface area and high chemical reactivity, smaller particles (less than 1 nanometer) may be preferable. This is especially relevant in catalytic applications and chemical product manufacturing. However, it’s important to ensure that smaller particles do not agglomerate, which could negatively impact their utility.

- Electrical and thermal conductivity: If the application focuses on electrical and thermal conductivity, powder with 99.99% copper content and larger particles may be preferable. Higher copper content and larger particle size can contribute to better conductivity in electrical and heat dissipation applications.

- Cost: Copper purity and particle size influence the cost of copper powder. Material with higher purity and smaller particles generally tends to be more expensive to produce.

- Compatibility with the manufacturing process: It’s important to consider whether the chosen copper powder is compatible with the specific manufacturing process of your application. Some processes may require specific powder characteristics to achieve desired results.

Ultimately, the choice between these two options will depend on the priorities and specific requirements of your application. If copper purity and electrical conductivity are key factors, you may prefer the option with 99.99% copper content. If high chemical reactivity and surface area are essential, the option with smaller particles may be more suitable. In any case, it’s essential to conduct specific tests and evaluations to ensure that the selected copper powder meets the goals of your application.

PRICE QUALITY % COPPER VS. PARTICLE SIZE

The determination of the price of the two types of Ultrafine Copper Powder you mentioned, one with 99.99% copper content and particles larger than 1 nanometer, and the other with 98.8% copper content but with particles smaller than 1 nanometer, depends on various factors and considerations and can vary depending on the supplier, quantity purchased, quality, and other aspects.

In general, copper powder with a higher copper content (99.99%) is often more expensive than the one with slightly lower copper content (98.8%). Material purity is an important factor that influences the price, as production processes to achieve higher purity can be more costly.

However, particle size can also affect the price. Producing nanoscale particles often involves more advanced and expensive manufacturing processes, which could offset the difference in copper purity in terms of costs.

Ultimately, the best way to determine which of the two options is more expensive in your specific situation would be to contact suppliers of these materials and request quotes based on your exact requirements, desired quantity, and other specific factors. This will allow you to obtain an accurate estimate of the cost of each type of ultrafine copper powder for your particular application.